As an electrical contractor, your reputation is built on reliability, safety, and precision. While the bulk of your work often lies within a building’s walls, the rooftop represents a unique environment with its own set of challenges. One area often overlooked, yet critical for the long-term integrity of your installation and the building itself, is the proper support of rooftop electrical conduit.

Far too often, we see makeshift solutions like scrap wood or even bricks used to support conduit runs on roofs. While these might seem like quick fixes, they can lead to costly problems down the line – from compromised roof membranes to unstable electrical infrastructure. This guide will walk you through why dedicated non-penetrating roof conduit supports are not just a best practice, but an essential component of any professional rooftop electrical installation.

The Problem with Makeshift Supports

Imagine a meticulously installed electrical system inside a building, only to find its outdoor components resting precariously on deteriorating lumber. This scenario is unfortunately common. Wood blocks absorb moisture, leading to rot, mold, and eventual collapse. They can shift, leading to conduit stress, or worse, abrade the roof membrane as they move with thermal expansion and contraction.

Traditional solutions that penetrate the roof, while sometimes necessary, introduce potential leak points, voiding warranties and creating future headaches for building owners. This is where engineered, electrical conduit roof supports become invaluable.

Why Choose Engineered Roof Conduit Supports?

Dedicated rooftop support systems are designed with the unique demands of the rooftop environment in mind. Here’s why they’re the superior choice:

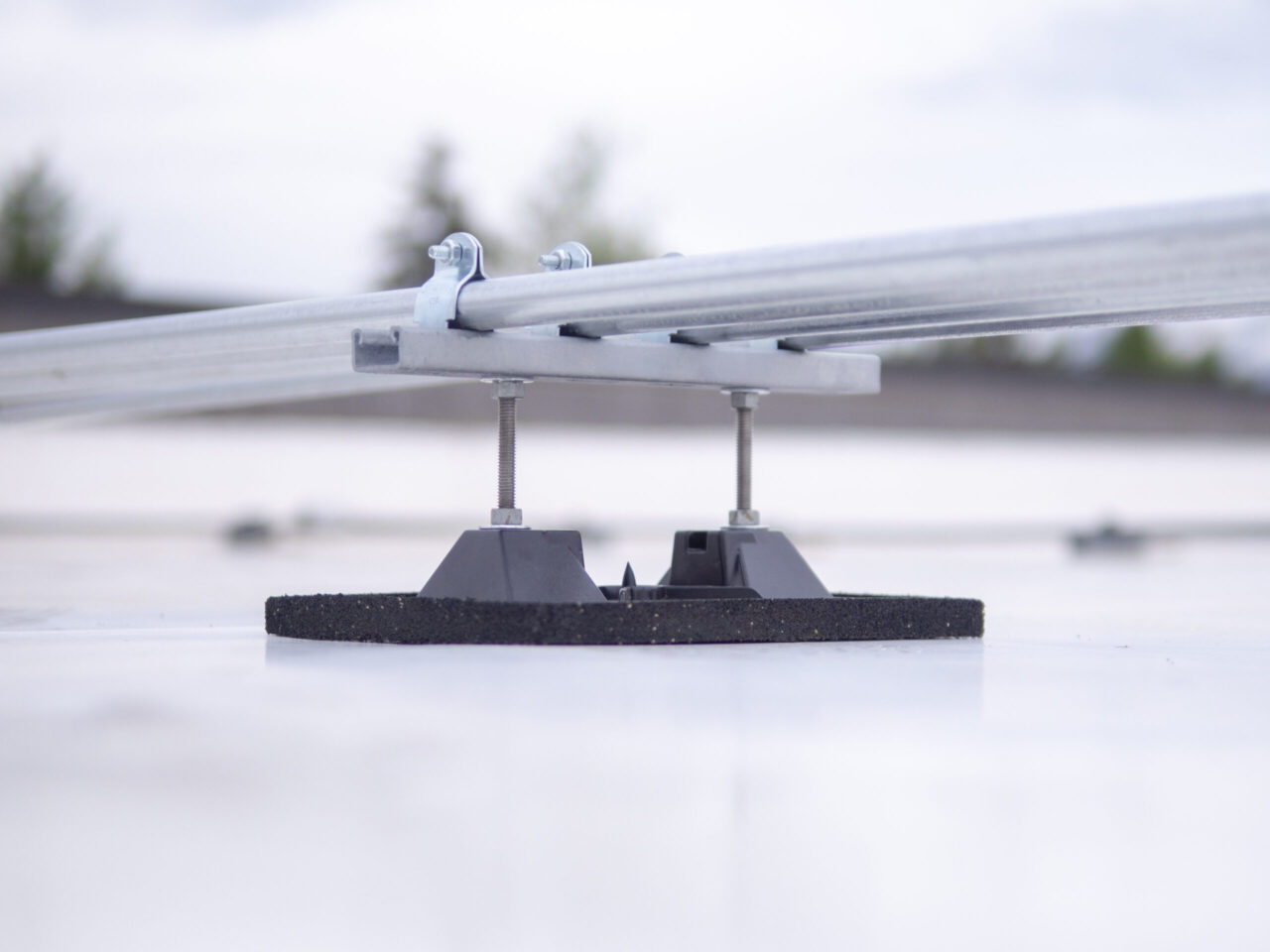

- Roof Membrane Protection: This is paramount. Non-penetrating supports distribute the weight of the conduit evenly, preventing damage to the sensitive roof membrane. They are typically made from materials like recycled rubber or durable plastics that are inherently non-abrasive and resistant to UV rays, extreme temperatures, and chemicals. This protects the building owner’s roof warranty – a significant selling point.

- Stability and Durability: Unlike loose bricks or rotting wood, engineered roof blocks for conduit provide a stable, long-lasting base. They are designed to withstand wind uplift and maintain their position, ensuring your conduit runs remain secure and in place for decades. This stability prevents conduit movement, which can otherwise stress fittings and connections.

- Professional Aesthetic and Organization: A well-supported conduit system doesn’t just function better; it looks better. Clean, organized runs supported by uniform conduit roof support blocks reflect professionalism and attention to detail. This is particularly important for commercial and industrial roofs where complex electrical systems are common. Organized conduit also simplifies future maintenance and troubleshooting.

- Compliance and Safety: Many building codes and industry best practices require specific support for rooftop installations. Utilizing purpose-built roof conduit support blocks helps ensure your installations meet these standards, reducing liability and enhancing overall safety.

Key Considerations When Selecting Your Roof Conduit Supports

When choosing the right electrical conduit roof supports for your next project, keep the following in mind:

- Material: Look for UV-stabilized, weather-resistant materials that won’t degrade over time or react negatively with the roof membrane. Recycled rubber bases are popular for their excellent grip and cushioning properties.

- Height and Adjustability: Different roof slopes and conduit sizes may require varying support heights. Adjustable options allow for leveling and accommodate variations in roof surfaces.

- Load Capacity: While conduit is lighter than pipework, ensure the supports can handle the weight of multiple conduits if you’re creating a high-density run.

- Ease of Installation: Non-penetrating systems are typically quick and easy to install, saving valuable time on the job site.

Elevate Your Rooftop Electrical Installations

Moving beyond makeshift solutions to engineered roof conduit supports is a clear sign of a commitment to quality and longevity. By investing in proper electrical conduit roof supports, you protect the building owner’s assets, enhance the safety and aesthetics of your work, and ultimately, reinforce your reputation as a top-tier electrical contractor.

Don’t let the last few feet of your electrical run compromise the entire installation. Choose durable, non-penetrating roof blocks for conduit to ensure your rooftop electrical infrastructure stands the test of time and the elements.

The team at MIRO is ready to help. Request a Quote or Request a Free Rooftop Design Consultation to work with our experts on selecting the right support system for your application.