Feeling overwhelmed by the task of addressing wind loads for equipment on your roof and you don’t want to penetrate the roof membrane? You are not alone. In your quest to find the most wind load optimized roof support system, here are some options you have along with the pros and cons of each.

To understand the task at hand, keep in mind that the goal is to optimize the load path. The load path is a reaction applied to equipment and transferred to the support system, and then transferred to the roof structure.

Wind Load Solution 1: More Weight (Ballast)

One approach is to add enough weight to counteract the loads wind would apply.

Pros of Ballast:

- Ballast allows a system that will not penetrate the roof or require any mechanical attachments.

- The design would include a very stable support system.

- This option will reduce the price of roof modifications and work.

- Easier to replace roof supports and perform roof maintenance over time.

Cons of Ballast:

- Adding enough weight to counteract proposed wind load reactions requires significant amounts of weight added to the rooftop.

- It is challenging to add enough weight while also increasing surface area to distribute that weight to protect the roof membrane and roof insulation.

- Because it typically requires an additional 500 – 1,200 LBS per support, the extra weight may be problematic for the building structure.

- The supports are very large and expensive and are more involved to install.

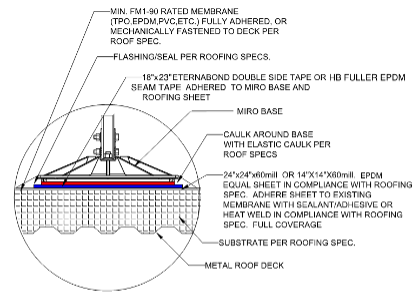

Wind Load Solution 2: Adhesives

This option uses a non-penetrating support and adheres the bases of the supports to the top of the roof membrane.

Pros of Adhesive:

- Allows a system to be placed without mechanically fastening any supports to the structure of the building (roof penetrations).

- Supports method is economical.

Cons of Adhesive:

- All reaction loads are transferred to the top of the roof membrane which could void the warranty of roof membrane.

- An adhesive is more difficult to validate by an engineer. Adhesive has different adhesion values depending on temperature.

- Adhesive may have chemicals that will slowly eat away at the roofing material or the material of the support base over time, reducing the lifespan of the roof or the support base.

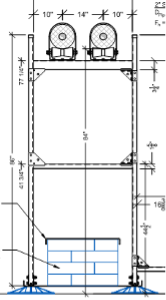

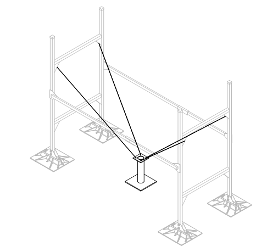

Wind Load Solution 3: Tie Downs

Another option is to use tie down cable restraints in conjunction with non-penetrating supports.

Pros of Using Tie Downs:

- Comprehensive analysis that is easier to predict and validate the proposed reaction loads by an engineer.

- Allows the support system and the wind system to be separate. This help will roof maintenance and future re-roofing. This will also help separate the scope of work for different trades.

- May not need as many locations for mechanical attachment.

- This option opens the door to alternative attachment options (i.e. U-Anchors www.anchorproducts.com)

- This option works well with traditional mechanically fastened options. (i.e. pipe stanchion and welded bases plate).

- Stands are very modular (free floating stands)

Cons of Using Tie Downs:

- Roof penetration and mechanical attachments are required.

- Cable routing and attachments could become obstructions and tripping hazards on the roof.

- May not provide enough rigidity or resistance for all applications.

- If equipment is low to the roof, the cabling may not work.

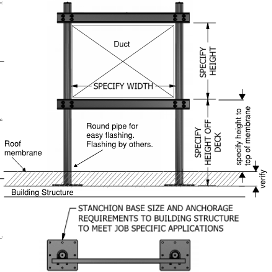

Wind Load Solution 4: Direct Support Attachment

Direct attachment supports, as the name implies, are attached directly to the building structure.

Pros of Direct Attachment:

- This approach allows for a comprehensive and validated engineering analysis and values.

- Allows a mix between mechanically attached supports and alternating non-penetrating supports (usually every other support needs to be mechanically fastened depending on application).

- Will work in any area from California to Florida and meet any applicable wind loads.

- Supports are fabricated to meet job specific conditions.

- Generally the preferred attachment method of Structural Engineers.

- Works with all types of roof decks (concrete, precast, wood, metal, composite)

Cons of Direct Attachment:

- Higher costs.

- Attachment points and roof penetrations required.

- Involved installation process.

As you can tell there is a balance that you will need to strike between risk, cost, and timeline when deciding what option for rooftop supports are best for your project. When everyone on the project is on the same page with the direction, MIRO can provide the most optimized support method possible. Contact a MIRO professional today for a consultation.